Custom Metal Fabrication & Specialist Welding Services

Quality Craftmanship

What we do

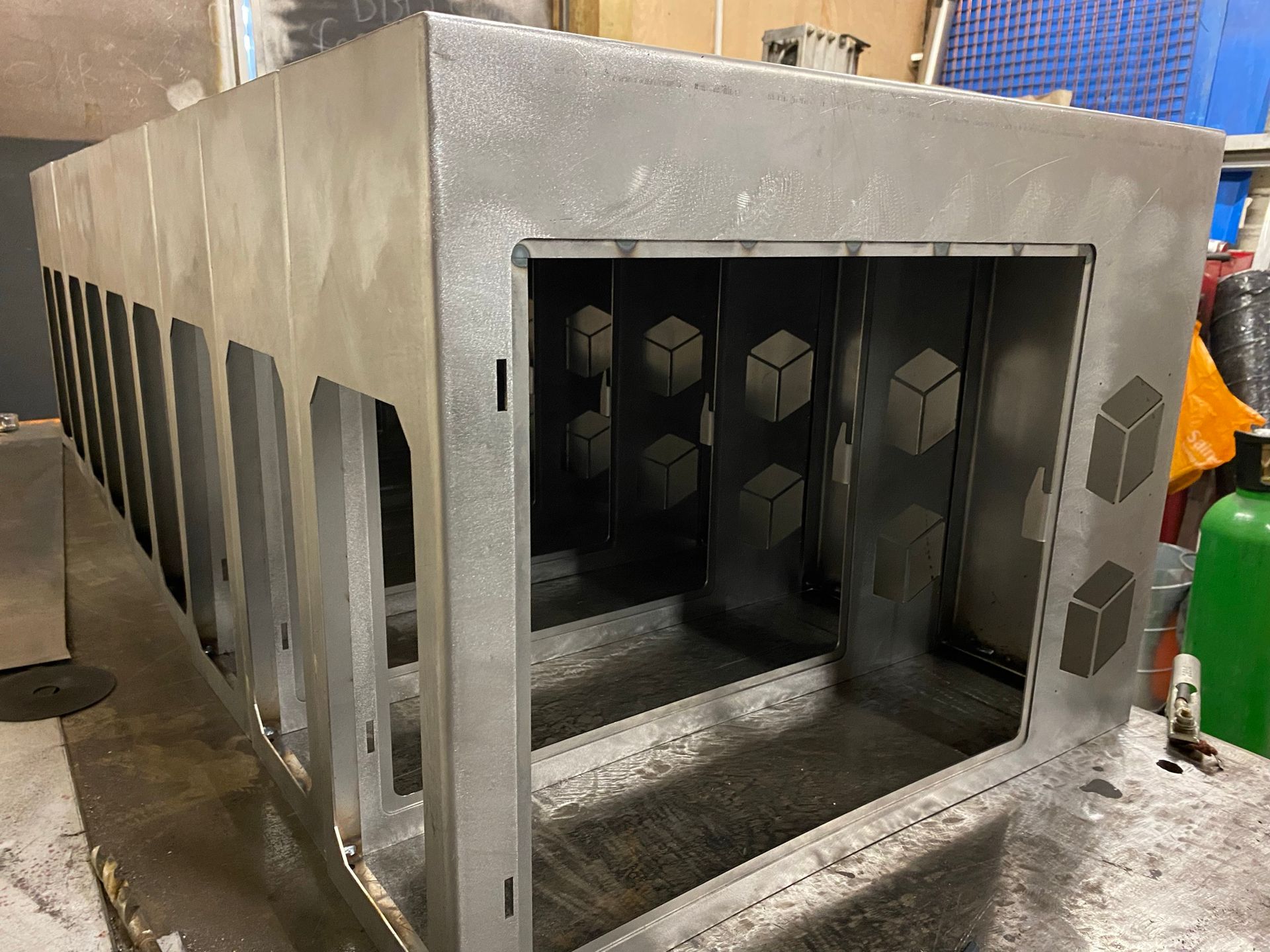

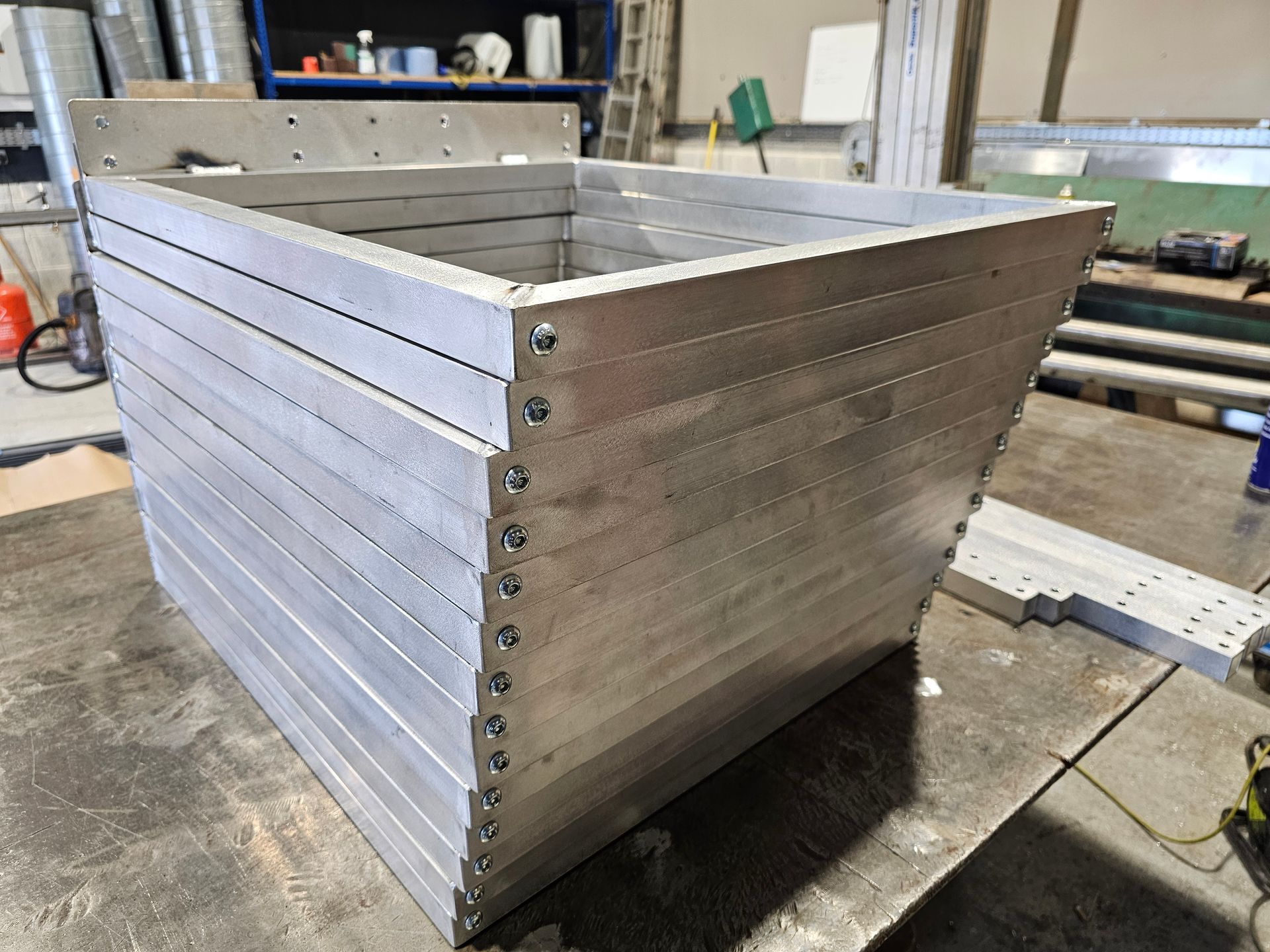

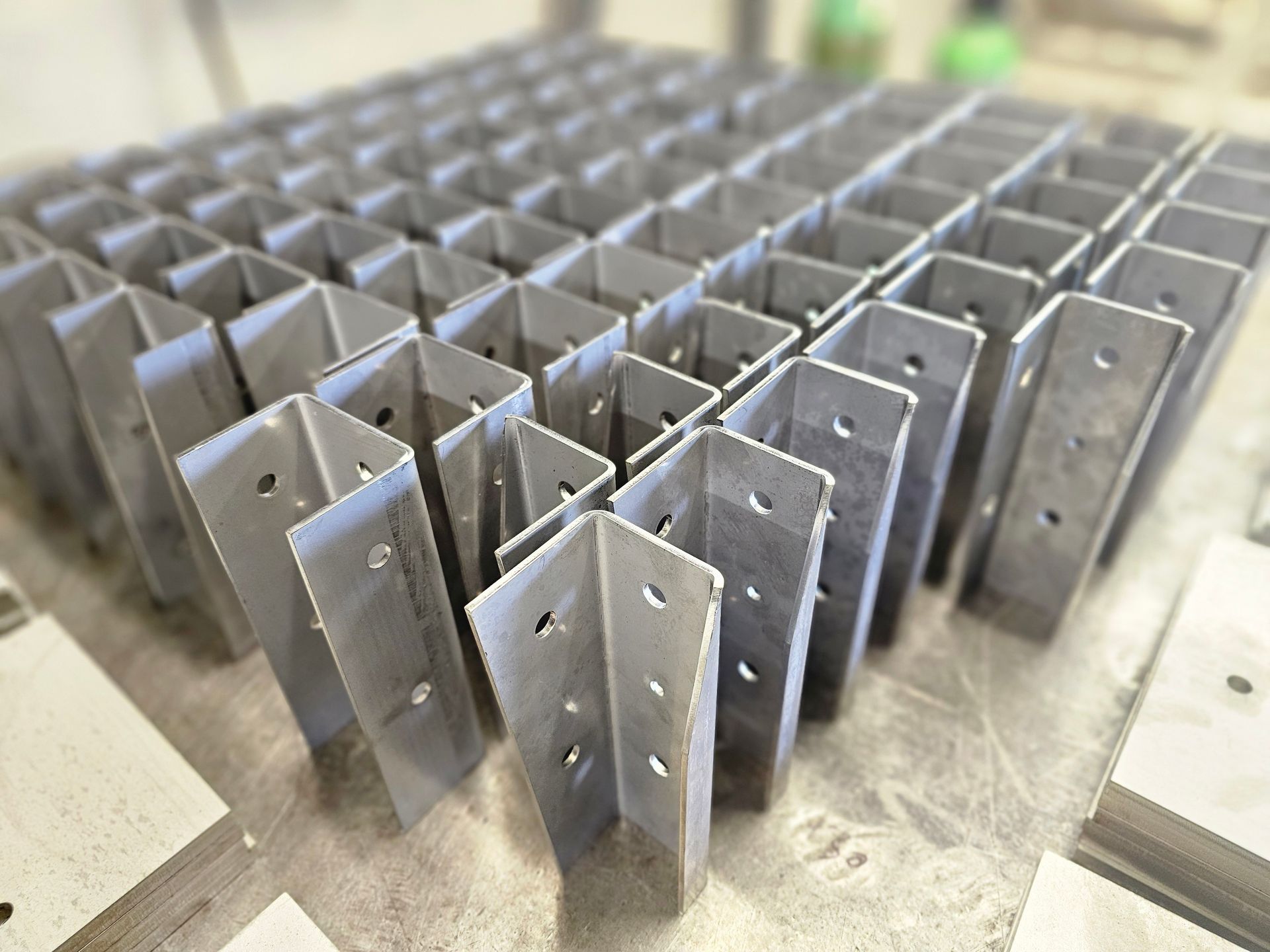

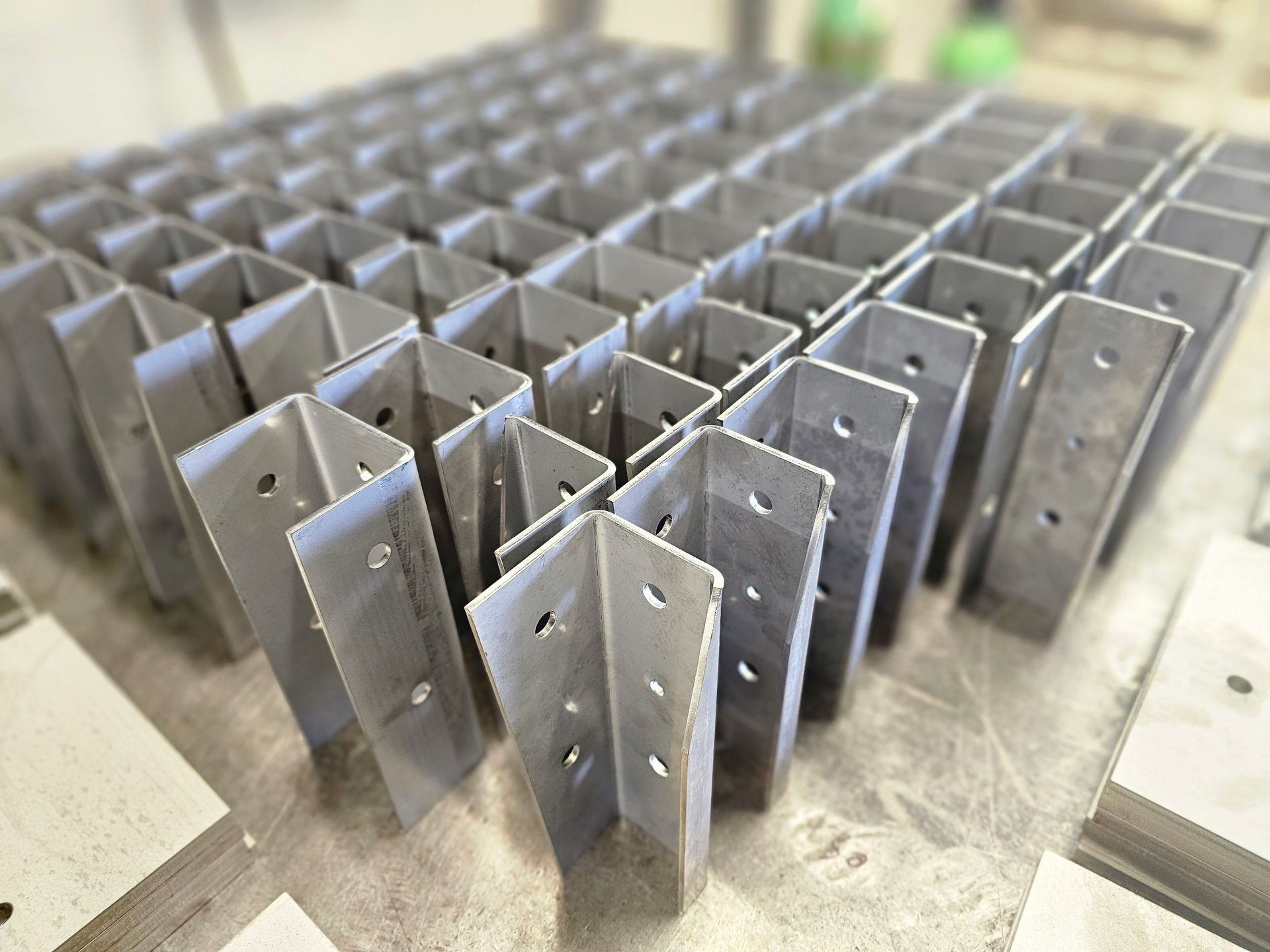

At Perfect Fabrications, we specialize in the design and fabrication of one-off parts, as well as small and large batch production. Our capabilities include design services, MIG, TIG, and stick welding, drilling, tapping, cutting, finishing, steel folding, and inserting.

Highly Skilled Welders

Materials

With this comprehensive range of processes, there’s little we can’t handle. We work with a variety of materials, including stainless steel, aluminium, mild steel, galvanized steel, and brass. To complete the package, we also offer a full assembly service.

Available Processes

Metal Grades

Capabilities

Our capabilities are suitable for any size of business needs.

We collaborate with reliable partners to guarantee that we can consistently cater to everyone's unique needs; no task is too large or too small.

Metal Fabrication

What is welding and fabrication?

Fabrication involves a range of processes, including welding, cutting, grinding, and sanding. While metal fabrication refers to the comprehensive procedure that a component undergoes, welding constitutes an integral aspect of this overall process.

Welding occurs when two metal pieces are joined through the application of heat. This heat generates a weld pool that solidifies upon cooling, forming the joint that unites the two pieces. Typically, this joint is stronger than the original metal.

TYPES OF WELDING

Different Types of Welding Explained

There are several welding techniques available, such as MIG (Metal Inert Gas), MAG (Metal Active Gas), TIG (Tungsten Inert Gas), and synergic welding. Each welding method serves distinct applications and offers unique benefits.

Our fabricators are certified to weld a broad spectrum of material thicknesses in both stainless steel and mild steel. They have undergone a stringent testing process conducted by an external certification body to confirm our compliance with this standard.

Expertise

Metal fabrication is a skilled industry; our team of expert welders and fabricators work hard to always be at the top of their game. You can rest easy knowing that our specialist team has years of experience working in the industry; they are always on hand to help you turn your ideas into reality.

Bespoke

Our team will guide you through the process to ensure that you get a custom product for your needs. We will work with you to get the suitable materials and sizes for the job, helping keep wastage to a minimum so that the job is as cost effective as possible.

Durability

Sheet metals are one of the most durable materials and are resistant to most high pressures; they can be folded into nearly any shape required. When sheet metal is produced, it is finished to ensure that it can withstand moisture, sun rays and corrosion, which means you will have a long lasting, low maintenance end product.

Quality

Our expert team always uses the latest techniques and technologies when fabricating metal, ensuring that all our work is precise and accurate. No piece leaves our workshop without having first been passed by our quality assurance team, ensuring that our standards are always the highest.

Advantages

What are the advantages of fabrication?

Metal fabrication has many advantages that make it the perfect choice for your sheet metal needs.

FAQs

Everything you need to know about welding

We have the answers to all your welding questions, have a look at our frequently asked questions. If you can’t find the answer you are looking for, then get in touch, and a team member will be on hand to help you with any questions you might have. Call us on 01684 210 610 or send us an email.

What is TIG Welding?

Tungsten inert gas welding (TIG welding) is the process of welding using electricity to melt and join pieces of metal together. It combines an electrode, which heats the metal, and a gas (typically Argon) which protects the weld puddle from airborne contaminants. It was initially invented in the 1940s as a better way to weld magnesium and aluminium together; it is now a widely used practice due to its versatility, cleanliness, and minimal finishing requirements.

What is MIG Welding?

Metal Inert Gas Welding (MIG Welding) is the most common type of welding. It is an arc welding process where a continuous solid wire electrode is fed through a welding gun into the weld pool. This is what brings the two base materials together, forming a join. MIG welding also uses a shielding gas to protect the weld pool from airborne contaminants.

What are the 3 main types of welding?

The three main types of welding are stick welding also known as Shielded Metal Arc Welding (SMAW), Tungsten Inert Gas (TIG) welding and Metal Inert Gas (MIG) welding.

What is the difference between MIG and TIG welding?

The difference between the two is how the arc is used. In MIG welding, a wire feed constantly moves through the gun to create the spark; this melts to form the weld. In TIG welding, long, handheld rods are manually fed into the weld puddle whilst the electrical current is varied with either a touch mounted control or a foot pedal.

How do you ensure you protect your welders from dangerous fumes?

We work hard to ensure that our welders are protected from harmful fumes. We use extraction LEVs at every station and have air masks available for each welder. Extraction LEVs (Local Exhaust Ventilation) capture hazardous fumes and remove them from the entire workplace, keeping the individual welder safe and the whole workshop. Air masks protect the individual welder from dangerous fumes by stopping the fumes from entering their personal breathing space.

OUR SERVICES

See what else we do

We have a wide range of metal fabrication services available for your business needs. Please take a look at the other services we have available.

GET IN TOUCH

Request a free quote

To learn more about our services and get a bespoke quote, please don’t hesitate to contact the team on 01684 210 610 or click the button below.